Are Diesel Additives Worth It? We Break Down CRD Fuel Enhancer

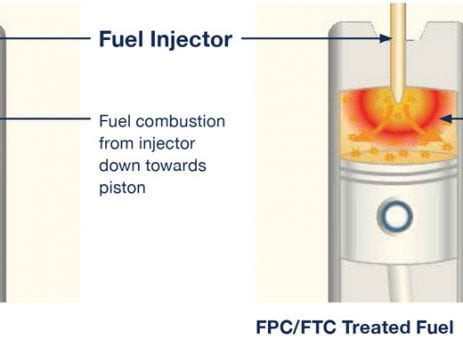

There is no shortage of off-the-shelf fuel additives available these days, but what are you really putting in your tank? With so many products out there, it's hard to know what or why you should be using them at all. CRD Fuel Enhancer is a concentrated diesel fuel additive designed to: Restore...