CEM Landmarks and Achievements

While mining and other large consumers are important, at Cost Effective Maintenance, we remain passionate about the needs of our private and small fleet customers, many of whom have become like family. Working closely with individuals and small fleet operators has been, and is today, a vital part of both our research, and the field stages of our research and development work.

A chronological timeline of CEM landmarks:

1984. Cost Effective Maintenance established.

Brid became involved with speciality high performance lubricants, and applications for fuel additive chemicals.

1985. NSW Department of Mines – Independent Study completed on CEM products

1986. Brid Walker left CSIRO as Technical Officer to fully establish Cost Effective Maintenance.

1986. Pioneered the fix for diesel engine oil turning black as soon as it’s changed (FTC Decarbonizer and the flushing out of crank cases).

1986. Pioneered procedures that have since saved many thousands of engines from mechanic recommended rebuilds.

1986. Kept older vehicles and machinery in commercially productive service for much longer.

1989. WA Institute of Technology, Perth WA – Independent study completed.

1991-2. Tarong Coal Mine (Rio Tinto mine sites) – FTC Decarbonizer successfully used to reduce fuel costs.

1991-2. Kidston Gold Mine NQ – FTC Decarbonizer successfully used to reduce mobile equipment fuel costs on site.

1991. Porgera Gold Mine, PNG – CEM recommended engine modifications and FTC Decarbonizer use to successfully lower horrific levels of diesel smoke in high altitude environment.

1991. CEM developed their much improved Flushing Oil Concentrate

1992. Developed AW10 Antiwear. Reduced operating temperature, stress and wear rates in gearboxes (both manual and automatic), diffs, final drives, hydraulics.

2001. Queensland Rail QR – CEM demonstrated an effective, low cost means of eliminating locomotive exhaust spark throwing. Trackside fires can cause $millions worth of property damage. Testing was conducted at QLD Rail’s Redbank Load Bank facility with a “shunting locomotive”, # 1762D.

2001. . Tarong Coal. FTC Decarbonizer was re-introduced into the open cut mining fleet for the remaining years of Rio Tinto ownership. Apart from improved fuel economy and reduced smoke emissions, engine condition and service life improvements were noted. Diesel bulk fuel tanks were cleaner due to control of fuel growths.

2002. Western Australian Iron Ore Mine. Fuel treated with FTC Decarbonizer

2003. Increased coal production efficiency at a Rio Tinto mine.

2003. Western Australian Gold Mine. Fuel treated with FTC Decarbonizer.

2005. Western Australian Nickel Mine. Fuel treated with FTC Decarbonizer.

2005. University of Western Australia (UWA) – This independent study confirmed fuel efficiency benefits in Caterpillar powered generators, both “as new” and “mid-life”, and at 3 different load settings.

2007. BMA Peak Downs Mine – Operators of Caterpillar D11R dozers were getting 8000-10,000hrs engine life, with many failures as early as 3000-4000hrs. This was against a Caterpillar recommended 12,000hr overhaul. Caterpillar couldn’t come up with a fix, yet CEM brought a fleet of 10 x D11R’s to 18,000hrs service life… a clear 50% above Caterpillar target!

2008. CEM relocated to a larger premises in Sumner Park (current address)

2011. Pioneered a low cost fix for common rail diesel engine problems. These injectors were commonly regarded as being delicate and easily destroyed, and cost typically $2000 each to replace. CRD Fuel Enhancer easily fixed 90% of injector rattles, debunking the myth that they should be replaced every 100,000kms!! We have customers with over 600,000kms on their original CRD injectors.

2012. University of Western Australia (UWA) – Published an independent study on FTC Decarbonizer, confirming positive results on exhaust soot reduction.

Under the leadership of Prof Zhang, this study confirmed fuel efficiency, reduced smoke particulates.

2015. Cost Effective Maintenance commenced regular shipping to the USA.

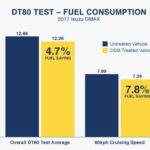

2017. Brisbane City Council/Buses – BBC Technician conducted a DT80 Emissions test, which confirmed fuel efficiency and faster acceleration (more power) with CEM’s Diesel Performance Pack.

2018. Commenced commercial distribution to the USA with Pro Maintenance Additives.

CEM Landmarks and Achievements

While mining and other large consumers are important, at Cost Effective Maintenance, we remain passionate about the needs of our private and small fleet customers, many of whom have become like family. Working closely with individuals and small fleet operators has been, and is today, a vital part of both our research, and the field stages of our research and development work.

A chronological timeline of CEM landmarks:

1984. Cost Effective Maintenance established.

Brid became involved with speciality high performance lubricants, and applications for fuel additive chemicals.

1985. NSW Department of Mines – Independent Study completed on CEM products

1986. Brid Walker left CSIRO as Technical Officer to fully establish Cost Effective Maintenance.

1986. Pioneered the fix for diesel engine oil turning black as soon as it’s changed (FTC Decarbonizer and the flushing out of crank cases).

1986. Pioneered procedures that have since saved many thousands of engines from mechanic recommended rebuilds.

1986. Kept older vehicles and machinery in commercially productive service for much longer.

1989. WA Institute of Technology, Perth WA – Independent study completed.

1991-2. Tarong Coal Mine (Rio Tinto mine sites) – FTC Decarbonizer successfully used to reduce fuel costs.

1991-2. Kidston Gold Mine NQ – FTC Decarbonizer successfully used to reduce mobile equipment fuel costs on site.

1991. Porgera Gold Mine, PNG – CEM recommended engine modifications and FTC Decarbonizer use to successfully lower horrific levels of diesel smoke in high altitude environment.

1991. CEM developed their much improved Flushing Oil Concentrate

1992. Developed AW10 Antiwear. Reduced operating temperature, stress and wear rates in gearboxes (both manual and automatic), diffs, final drives, hydraulics.

2001. Queensland Rail QR – CEM demonstrated an effective, low cost means of eliminating locomotive exhaust spark throwing. Trackside fires can cause $millions worth of property damage. Testing was conducted at QLD Rail’s Redbank Load Bank facility with a “shunting locomotive”, # 1762D.

2001. . Tarong Coal. FTC Decarbonizer was re-introduced into the open cut mining fleet for the remaining years of Rio Tinto ownership. Apart from improved fuel economy and reduced smoke emissions, engine condition and service life improvements were noted. Diesel bulk fuel tanks were cleaner due to control of fuel growths.

2002. Western Australian Iron Ore Mine. Fuel treated with FTC Decarbonizer

2003. Increased coal production efficiency at a Rio Tinto mine.

2003. Western Australian Gold Mine. Fuel treated with FTC Decarbonizer.

2005. Western Australian Nickel Mine. Fuel treated with FTC Decarbonizer.

2005. University of Western Australia (UWA) – This independent study confirmed fuel efficiency benefits in Caterpillar powered generators, both “as new” and “mid-life”, and at 3 different load settings.

2007. BMA Peak Downs Mine – Operators of Caterpillar D11R dozers were getting 8000-10,000hrs engine life, with many failures as early as 3000-4000hrs. This was against a Caterpillar recommended 12,000hr overhaul. Caterpillar couldn’t come up with a fix, yet CEM brought a fleet of 10 x D11R’s to 18,000hrs service life… a clear 50% above Caterpillar target!

2008. CEM relocated to a larger premises in Sumner Park (current address)

2011. Pioneered a low cost fix for common rail diesel engine problems. These injectors were commonly regarded as being delicate and easily destroyed, and cost typically $2000 each to replace. CRD Fuel Enhancer easily fixed 90% of injector rattles, debunking the myth that they should be replaced every 100,000kms!! We have customers with over 600,000kms on their original CRD injectors.

2012. University of Western Australia (UWA) – Published an independent study on FTC Decarbonizer, confirming positive results on exhaust soot reduction.

Under the leadership of Prof Zhang, this study confirmed fuel efficiency, reduced smoke particulates.

2015. Cost Effective Maintenance commenced regular shipping to the USA.

2017. Brisbane City Council/Buses – BBC Technician conducted a DT80 Emissions test, which confirmed fuel efficiency and faster acceleration (more power) with CEM’s Diesel Performance Pack.

2018. Commenced commercial distribution to the USA with Pro Maintenance Additives.