FPC – Fuel Performance Catalyst

Get more out of your fuel with FPC – the superior diesel fuel additive

Manufactured in Australia, FPC is a combustion catalyst specifically formulated to provide significant benefits to fuel consumers. A true combustion catalyst, this superior diesel fuel additive is used worldwide by small and large diesel consumers, including the mining, power generation, rail, marine and transport industries.

What’s the difference between FPC and other fuel additives?

Many products available on today’s market – including those supplied by oil companies – are generally surfactants or detergents. By contrast, FPC acts upon the combustion process itself, promoting a more complete burn of the fuel and eliminating problems associated with incomplete combustion such as hard carbon deposits and soot contamination in engine oil.

FPC has been independently tested and proven not to be just another ordinary fuel additive – it’s the best fuel additive! Here’s why…

Improved Fuel Economy

FPC promotes a more complete burn of fuel, enabling more energy to be released per unit volume of fuel. Consequently, less fuel is required to produce the same level of power output. This has been proven at some of the world’s leading testing facilities including SouthWest Research Institute San Antonio Texas, Centre for Energy at UWA (University of Western Australia) and CAD Railways Quebec Canada, with documented reductions in fuel consumption of up to 8%. These findings continue to be substantiated during field testing applying International Engineering Standard Test Procedures.

Scientific testing has provided indisputable evidence of the benefits of FPC.

Reduced Diesel Particulates (Smoke/Soot)

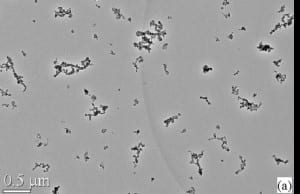

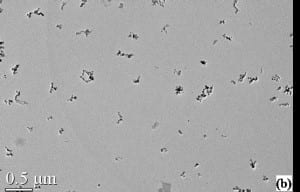

Diesel Particulate Matter (DPM) has been classified by the World Health Organisation as Carcinogenic. Studies recently conducted at UWA’s Centre for Energy have verified significant reductions in DPM of up to 39% following FPC treatment of fuel. FPC, by promoting a more complete combustion process, reduces both the number and size of soot particles as illustrated in the following Transmission Electron Microscopy images taken from samples of exhaust gases. This not only reduces contaminates in the engine but also in the air we breathe.

Studies recently conducted at UWA’s Centre for Energy have verified significant reductions in DPM of up to 39% following FPC treatment of fuel

Reduced Greenhouse Gas Emissions

Greenhouse gas emissions are detrimental to the environment and our health. Australia is one of the ninety-nine countries to be signatories to the United Nations convention on reducing Greenhouse Gases, and all industries are expected to play their part in helping to meet Australia’s goals.

FPC has been scientifically proven to reduce carbon monoxide emissions by 22% and unburnt hydrocarbons by 15% in a new engine.

Reduced Maintenance Costs

The more complete combustion process provided by FPC results in a reduction of varnish and hard carbon deposits. With these contaminants being the cause of many major maintenance problems, any reductions or removal will provide significant maintenance savings via reduced wear on engine parts such as pistons, valve stems, cylinder liners and injector tips.

Extended Engine Oil Life

Engine oil life can be significantly shortened by contamination of by-products arising from incomplete combustion. Carbon in the form of soot in the engine oil acts as an abrasive, causing engine-wear metals to contaminate the oil and reduce both the oil and engine life.

In summary, scientific testing and practical field trials have proven that FPC diesel fuel additive:

- Improves fuel economy

- Improves engine performance and life

- Reduces diesel particulates/smoke

- Reduces greenhouse gas emissions

- Reduces engine carbon deposits

- Extends injector life

- Prevents engine glazing

- Increases engine oil life

- Inhibits growth of algae in fuel storage

- Will not change fuel specifications