PMX 145 Fuel Biocide

From $339.00 incl. GST

PMX 145 is a non-hazardous fuel biocide that stays suspended in diesel and biodiesel to kill microbes, drop sludge for easy removal, and prevent regrowth long-term — while keeping fuel ASTM D975 compliant.

Soluble in both the water phase and fuel phase and can be treated at the terminal, Bulk Fuel Storage, Transported fuel, or specific service stations.

- Broad spectrum activity

- Rapid inhibition of microbial growth

- Long term fuel preservation

- Kills mold, yeast, bacteria & fungus in diesel/biodiesel

- Drops sludge to tank bottom for easy removal

- Remains suspended for full-tank coverage

- Acts as a biostat to prevent regrowth

- Description

- Independent Testing

- ASTM Testing

- Doseing Instruction

- How Does It Work

- MSDS / TDS Sheets / Prodcut Download

Description

PMX 145 Fuel Biocide – Diesel & Biodiesel Microbial Control

PMX 145 is a high-performance fuel biocide designed to eliminate and prevent microbial contamination (“diesel bug”) in diesel and biodiesel storage and fuel systems. Microbes such as bacteria, fungus, yeast, and mould grow where fuel meets water, producing sludge, acids, and corrosion that block filters and damage pumps and injectors.

PMX 145 stops contamination at the source and keeps fuel protected long after treatment.

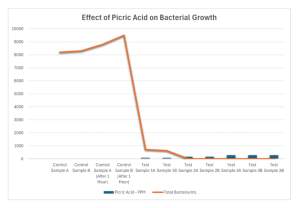

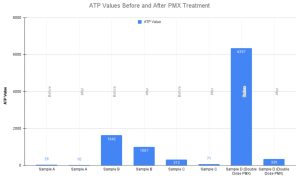

Summary – Independent Testing & Real-World Results

PMX145 has been independently verified under ASTM D975 and related standards, confirming treated diesel meets all fuel specifications with excellent results.

PMX145 – Independently Tested & Verified Under ASTM Diesel Standards

PMX145 – Independently Tested & Verified Diesel Fuel Treatment

PMX145 has been independently verified to meet and exceed international ASTM D975 and related diesel fuel standards. This ensures no reduction in fuel stability, and verified compliance with Australian and global fuel quality benchmarks.

Complete ASTM report for PMX treated Diesel Fuel, Results (Independent Laboratory Verification)

| ASTM / PMX Standard | Parameter | Result | Specification / Limit | Status |

|---|---|---|---|---|

| ASTM D975 | Diesel Fuel Specification Compliance | Meets All Requirements | Standard Diesel Fuel Specification | PASS |

| ASTM D5185 | Elemental Metals (Cu, Fe, V, Al, Si, Na, K, Mn, Ca, Mg, P, Zn) | <1 ppm | <2 ppm | PASS |

| ASTM D86 | Distillation (T10–T95) | 215–323 °C | 200–360 °C | PASS |

| ASTM D4052 | Density @15 °C | 846.9 kg/m³ | 820–860 kg/m³ | PASS |

| ASTM D93 | Flash Point | 64 °C | >61 °C | PASS |

| ASTM D445 | Kinematic Viscosity @40 °C | 2.5 cSt | 1.9–4.1 cSt | PASS |

| ASTM D5453 | Sulfur Content | 0.0007 % | <0.05 % | PASS |

| ASTM D2500 | Cloud Point | –3 °C | Within spec | PASS |

| ASTM D6079 | Lubricity (HFRR) | 0.406 mm | <0.520 mm | PASS |

| ASTM D2709 | Water & Sediment | <100 ppm | <200 ppm | PASS |

| ASTM D6469 | Microbial Contamination | <10 CFU/mL | <200 | PASS |

| ASTM D4176 | Visual Appearance | Bright & Clear | No haze / particulates | PASS |

| ASTM D1500 | Colour / Appearance | L1.0 – Light Amber | Clear to Amber | PASS |

| ASTM D613 / D287 | Cetane Index / API Gravity | 46.4 CI / 36 API | 40–55 CI / 30–45 API | PASS |

| ISO 4406 | Particulate Cleanliness Code | 19 / 16 / 12 | ≤ 20 / 18 / 15 | PASS |

| ASTM D1094 | Emulsion Test – Fuel & Interface Rating | No Harm | Maintain Base Fuel Rating | PASS |

| ASTM D130 | Copper Corrosion | Class 1 | Base Diesel Class 1 | PASS |

| ASTM D665 | Rust Prevention | No Harm | No Harm | PASS |

Summary of Findings

- ✅ No contamination or microbial activity detected (<10 CFU/mL).

- ✅ No reduction in llubricity (HFRR 0.406 mm).

- ✅ Ultra-low sulfur diesel maintained (0.0007%).

- ✅ Meets all ASTM D975 and related diesel fuel standards.

- ✅ Verified by an independent accredited diesel laboratory.

Learn more about our PMX145 Diesel Treatment.

Frequently Asked Questions

Has PMX145 been independently tested?

Yes. PMX145 has been independently tested by an accredited diesel analysis laboratory and verified under ASTM D975 and related diesel fuel standards. These tests confirm PMX145-treated diesel fuel is clean, stable, and meets all international quality requirements.

What does ASTM verification mean?

ASTM verification confirms that diesel fuel treated with PMX145 meets strict international standards for lubricity, cleanliness, and overall fuel performance. These certifications scientifically validate the effectiveness of PMX145, demonstrating that it reliably improves fuel efficiency, protects engines, and enhances operational performance according to recognized testing protocols.

PMX 145 Dosing Instructions

1. Standard Dosing

- Regular Treatment: 1:4000 PMX 145

- Ensures the fuel distribution system remains free from microbial growth.

- Note: Exceeding the recommended dosing provides no additional benefit.

2. Curative Treatment

- For heavily fouled systems: Use 1:2000 PMX 145

- May need to be repeated periodically to maintain microbial control.

- Gross contamination: Physical cleaning may be required to remove debris.

- Debris can be removed 6 hours after PMX 145 application.

3. Application by Vehicle Type

- Road Vehicles: Add PMX 145 directly to the vehicle fuel tank.

- Marine Vessels:

- PMX 145 can be added directly to tanks where manual cleaning is not feasible.

- Filter changes and debris removal may still be required.

- Storage Tanks:

- Add PMX 145 into a flowing fuel stream for optimal distribution.

- Both slug or continuous feed dosing can be used.

4. Important Characteristics

- PMX 145 is not surface active and will encourage water separation, not inhibit it.

- Heavily contaminated debris can be removed 6 hours after dosing.

5. Safety Precautions

- Avoid dermal contact.

- Wear suitable protective clothing including:

- Rubber gloves

- Safety goggles or face shield

- Follow appropriate safety procedures for all handling methods.

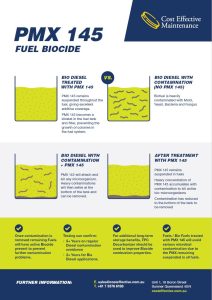

How PMX 145 Works

PMX 145 is a high-performance fuel biocide built to eliminate and prevent microbial contamination in diesel and biodiesel systems. Unlike treatments that separate or only work in part of the tank, PMX 145 remains suspended throughout the fuel, delivering full-volume additive coverage.

- Attaches to and Kills Microorganisms

Once introduced, PMX 145 targets active microorganisms including mould, yeast, bacteria, and fungus. It binds to these microbes and kills them, stopping contamination at the source.

- Drops Heavy Contamination Out of Suspension

As microbes die, the contamination agglomerates and settles to the bottom of the tank. This concentrates sludge in the low point, making removal easy via draining, water draw-off points, or tank cleaning.

- Remains in the Fuel for Full-Tank Protection

After the heavy contamination is removed, PMX 145 stays suspended in the fuel, so active biocide remains present across the entire tank and fuel system.

- Acts as a Biostat to Prevent Regrowth

PMX 145 continues working in both the fuel tank and filters, preventing microbial colonies from re-forming and keeping fuel protected long-term.

Proven Long-Term Protection

- 5+ years protection in regular diesel

- 2+ years protection in biodiesel applications

ASTM D975 Diesel Specification Compliance

PMX 145 protects fuel quality without pushing diesel outside specification. It meets ASTM D975 diesel fuel specification requirements.

| Standard | Test | Result | Spec Reference | Status |

|---|---|---|---|---|

| ASTM D975 | Diesel Fuel Specification Compliance | Meets All Requirements | Standard Diesel Fuel Specification | PASS |

Recommended Storage Pairing

For additional long-term storage benefits, PMX 145 can be paired with FTC Decarbonizer to improve combustion properties and overall fuel stability during storage.

- PMX 145 — kills and prevents microbial growth

- FTC Decarbonizer — supports cleaner burn and storage reliability

How it works Download Here