Cost Reductions in Driveline Maintenance

The key to this is minimizing operational stresses within gearboxes, differentials, planetaries, etc, since the less stress and loadings placed on each individual part within components, the longer everything lasts.

In this article, driveline maintenance and lubrication enhancements will be discussed. Stress reduction will require a lowering of the coefficient of friction between moving parts (gears, bearings, thrust washers, etc). That means that lubricated parts will move with less drag for the same load applied to them, and subsequently with less wear, and lower contact temperatures. Alternatively, for the same drag, withstand a greater load without additional wear or elevated temperatures.If friction reduction is significant, then noticeable improvements could include smoother operation, cooler operating temperatures, improved performance &/or efficiency, less noise and vibration.

AW10 Antiwear is one such product that has been demonstrated under controlled laboratory conditions, to reduce the oils coefficient of friction by up to 34%, when added to stock oils. Under similar lab conditions, frictional heat reduction was determined. A Sanderson Drill Rod (15 RMS, 100-120Rb) was rotated at 290 RPM under jaw load of 680kg via 2 V-bushings of SAE 4615-4620 Steel (16 RMS, 90 RB) for a period of 60 minutes. Lubrication was provided by a synthetic reference oil with added commercial ZDDP antiwear (an additive widely used by lube oil manufacturers). Bushing temperature stabilized at 218 deg C. The test was repeated using the same synthetic base stock, but with AW10 Antiwear, and resulted in a 69 deg C lower temperature. Reductions in wear rate of 88% and 96% (for AW10 concentrations equivalent to 73% and 109%, respectively, of the ZDDP product) were recorded. The torque required to drive the test rig was reduced by between 34% and 44% on two engine oils, indicating the potential for reduced machine frictional losses and efficiency.

In practical applications such as transmissions (both manual and automatic), differentials, planetaries and hydraulics,AW10’s benefits quantified in laboratory conditions translate into smoother operation, easier gear shifts, less wear, longer lasting equipment and lower operating temperatures.

AW10 Antiwear’s molecular polarity provides adherence to metal parts, which persists after shutdown and for the next cold start. The product also appears to penetrate more difficult to lubricate areas providing improved lubrication and reduced noise.

The high load carrying ability ensures far superior protection against abrasive & adhesive wear. It is suitable for engines, transmissions (incl automatic) as well as hydraulics. Its application is a very effective step in keeping all equipment in service for much longer.

Long term field experience is just as impressive…

Cost reductions in driveline maintenance.

Issues of overheating automatic transmissions in Mitsubishi Pajero 4×4’s are quite common, and customers are correcting this, by simply adding a little AW10 to the oil.

Pajero 2004 NP 3.2L DiD Auto. (John Tasker).While towing my 1500kg caravan I noticed that under load the transmission tunnel was becoming extremely hot. At 45,000km, I added a dose of AW10 at the rate of 1% to the auto transmission. Problem solved! I have now been using AW10 in my auto transmission for 45000km with no problems whatsoever. No more excessive heat and changes appear to be smoother. It had all its oils and fluids changed at the 90,000 km service, with AW10 again added to the AUTO TRANSMISSION. AW10 has been used in the diffs, transfer case, engine and power steering since new.

Road transport and earthmoving are other industry sectors which report operating improvements and cost reductions in driveline maintenance.

Freightliner FLC112. (Phil Riseley, Riseley’s Bulk Haulage).This prime mover is powered by a Series 60 Detroit with 18 speed Roadranger and Eaton diffs. Use of AW10 resulted in smoother gear shifts esp when cold. No click on fast changes. A slight engine rattle has also disappeared. Temperature reductions going up the Toowoomba range were 25F for the gearbox, 15F front diff and 20F rear diff!!

Earthmoving Fleet. Schulz Earthmoving uses AW10 throughout his fleet, in all components (eg hydraulics, engines, transmissions, final drives, etc). They report much cooler hydraulic temperatures in hard work applications eg Komatsu dozer during stick raking work. Before AW10, the hydraulics were too hot to put your hand on. When using AW10, it’s relative cool to touch. He had a scraper with a hydraulic pump chattering, and found that AW10 quietened it down considerably. He’s found it useful in a Komatsu PC300 excavator, and grader hydraulics.

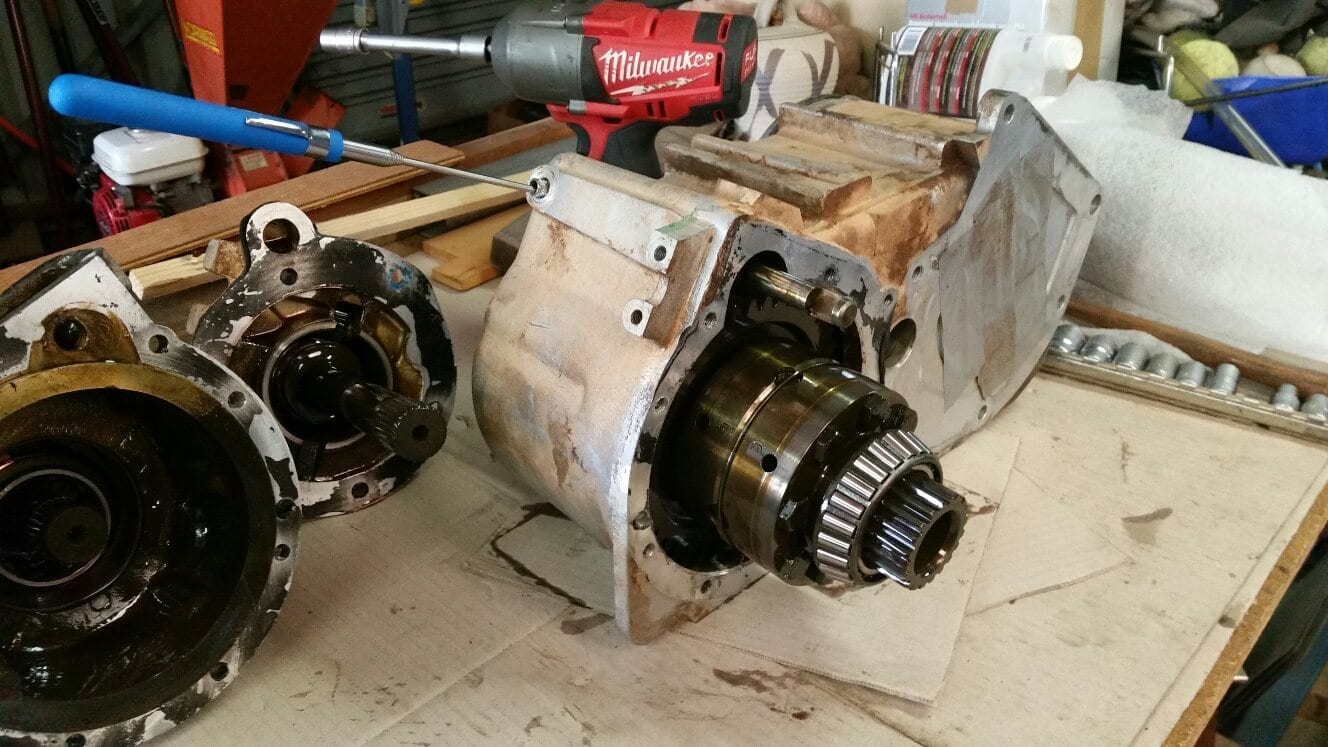

13 Speed Roadranger Overdrive Gearbox.

Marr’s Haulage ran 5 road trains, and tried AW10 instead of a $3000 repair job in one gearbox that had become very notchy. Gear shifting and operation immediately became smooth. Four (4) years later, and the gearbox was still in service. Use of AW10 in one of their engines resulted in a noticeable increase in oil pressure.

Lubrication Enhancements for driveline maintenance.

The greater the size, and the number of moving parts, the greater the component mass to put and keep in motion, and the greater are the frictional forces, which consume some of the fuel’s otherwise available power. This applies to engines (where numerous dynamometer tests have confirmed benefits), as well as transmissions and differentials and even hydraulics. What can be done to reduce frictional horsepower losses? The more widespread use of synthetic oils has allowed machinery manufacturers to design engines and transmissions which run on lower viscosity, oils, and that provides a minor, but important role in progressing efficiencies.

Ford Ranger with 6 speed manual. (Gary Scrivens ). Typically Rangers have a very clunky gear change & Gary also had a whine in top gear, and a noise in 3rd gear under load. The Ford dealer advised that this was normal for the vehicle. He used Molybond in the gearbox, and it was a little quieter. Then he decided to use AW10 in the gearbox and transfer case, so changed both oils. The gearbox was way quieter straight away, changed smoothly and the top gear whine had gone. A little noise still from 3rd, but much reduced. His fuel economy improved by 0.5L/100km!!! Just by using AW10 in the transmission. He noticed that when backing off to approach a red light, he actually has to brake more since there is less drag through the drive train.

Recommended products to reduce the cost of drive line maintenance…

-

Engine Overheating, Main-products, Oil Additives, Our Products

AW10 Antiwear

From $112.00 incl. GSTSelect options This product has multiple variants. The options may be chosen on the product page -