Fuel efficiency and emission reduction trial

FTC/FPC Combustion Catalyst

NSW Surface Mine

Final Report 2019

Introduction

FTC/FPC Combustion Catalyst, manufactured and supplied by Cost Effective Maintenance, has been tested and proven to reduce fuel consumption by up to 10% under varying load conditions while reducing carbon emissions and Diesel Particulate Matter (DPM). The addition of FTC/FPC results in improved combustion, allowing more of the energy from diesel to be converted to motive energy rather than being wasted as unburnt hydrocarbons exiting the exhaust or building up as abrasive hard carbon deposits within the engine.

Cost Effective Maintenance continues to subject FTC/FPC Combustion Catalyst to independent scientific testing. While engine design advancements have resulted in improved efficiency, FTC/FPC still provides additional efficiencies. This is because it acts on the combustion process itself, by catalysing the series of combustion reactions. So, regardless of the age, size or type of engine, or the specifications of the fuel, FTC/FPC use always results in a reduction in both fuel consumption and emissions.

More recently, the most comprehensive independent study ever conducted on FTC/FPC was completed. This rigorous four-year study was conducted at the University of Western Australia – Centre for Energy and was predominantly funded by the Australia Research Council. World renowned expert in the field of combustion Professor Dongke Zhang was commissioned to investigate the potential of FTC/FPC in reducing the carbon footprint of Australian industries.

Results released by the Centre for Energy UWA following extensive Laboratory and Dynamometer tests provided further evidence of significant reductions in:

- Exhaust particulates reduced by up to 39%

- Greenhouse gas emissions Reduced by up to 22%.

- Fuel consumption reductions in the region of 2.4% to 4.2% at variable loads in as-new engines following the introduction of FTC/FPC to diesel fuel was also realised

Professor Zhang stated that as these tests were conducted on as-new engines under controlled conditions, greater savings can be expected in the field.

Tests

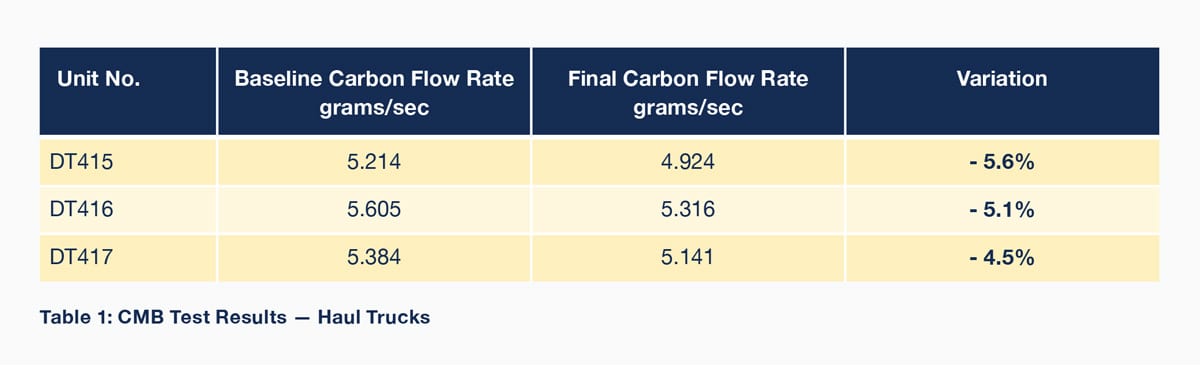

Baseline fuel efficiency tests were conducted on three haul trucks. Test methods included Carbon Mass Balance (CMB) and Diesel Particulate Matter (DPM) testing. Following baseline tests, a trial purpose fuel tank was provided with an automated dosing system installed allowing FPC treatment of the three test trucks to commence. Treated tests were then conducted.

- Baseline test

- Final test at 5 months

Test Methods

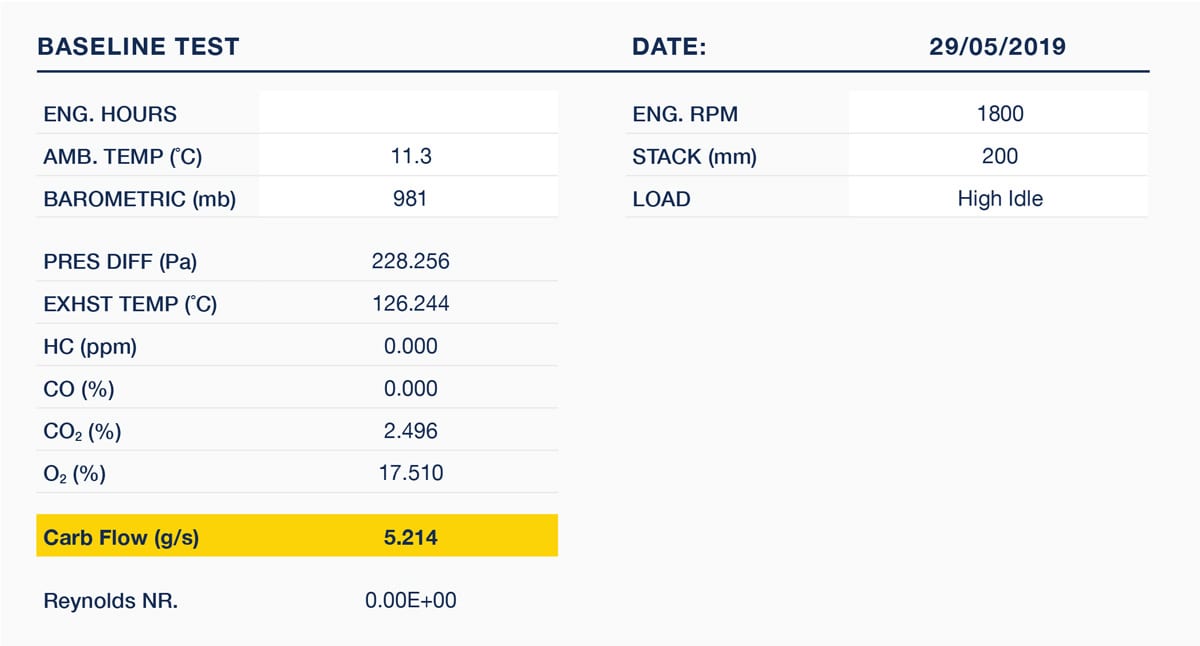

The Carbon Mass Balance Measurement (CMB)

CMB is a procedure whereby the mass of carbon exiting the exhaust is calculated as a measure of the fuel being burned. The elements measured via a TESTO five gas analyser include the exhaust gas composition, exhaust gas temperature, ambient temperature, exhaust pressure and barometric pressure. All readings together are entered into a calculation which produces a final reading in grams/per second flow of carbon exiting the exhaust.

This formula is derived from the international engineering standard test AS2077-1982 for measuring fuel efficiency. The CMB method is considered a reliable and accurate way to determine the efficiency of an engine, providing a percentage change figure of carbon exiting the engine which relates to carbon entering the engine in the form of fuel.

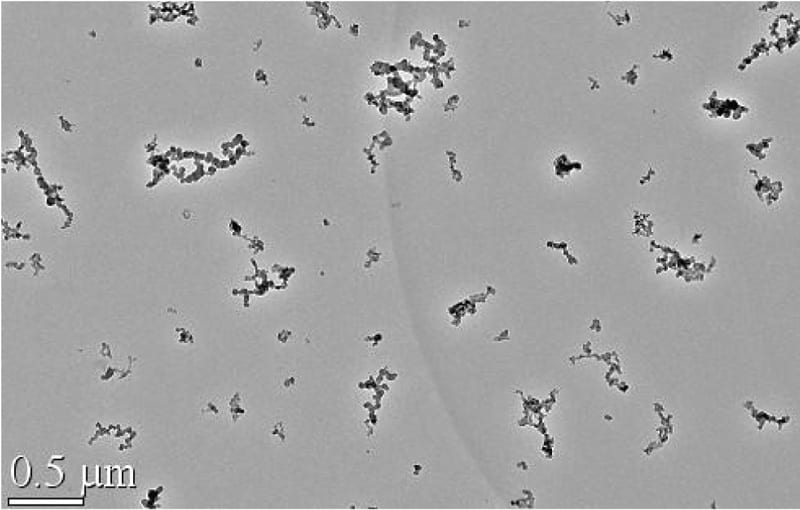

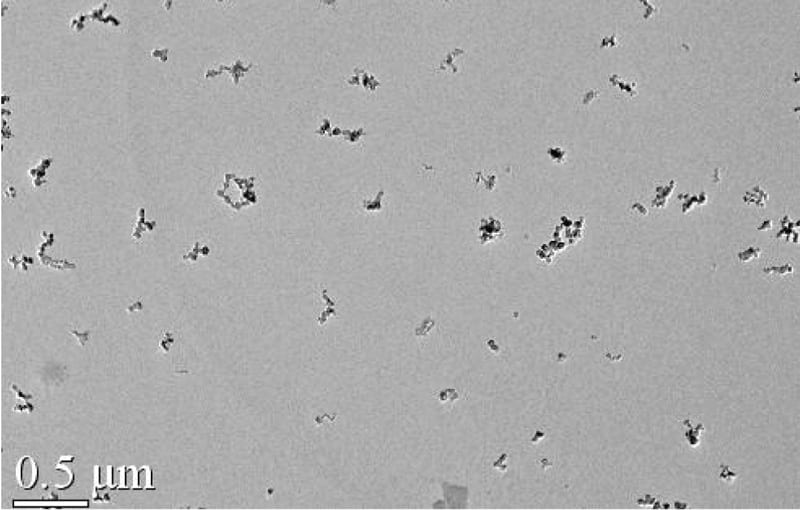

Diesel Particulate Matter (DPM) Test

DPM testing is conducted with a TSI AVT530 laser photometer instrument and provides a measurement showing mg/m³ of particulate matter exiting the exhaust.

All tests were conducted to the MDG 29 procedure which entails measuring DPM at 20 seconds idle, 20 seconds full throttle and return to idle for 20 seconds.

Test Results

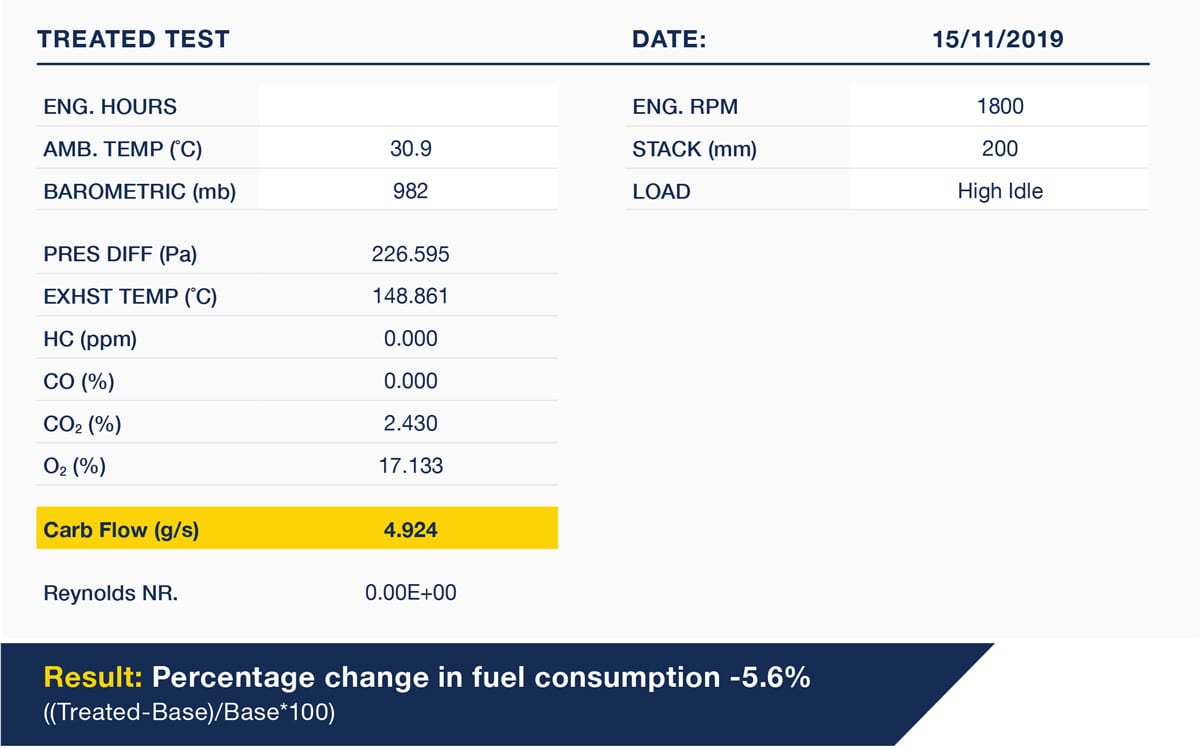

CMB Test Results – Haul Trucks

Average efficiency variation over the 3 haul trucks was a 5.07% reduction in grams/second flow of carbon which equates to a 5.07% reduction in fuel consumption at same engine load.

DT415 Haul Truck – CMB Results

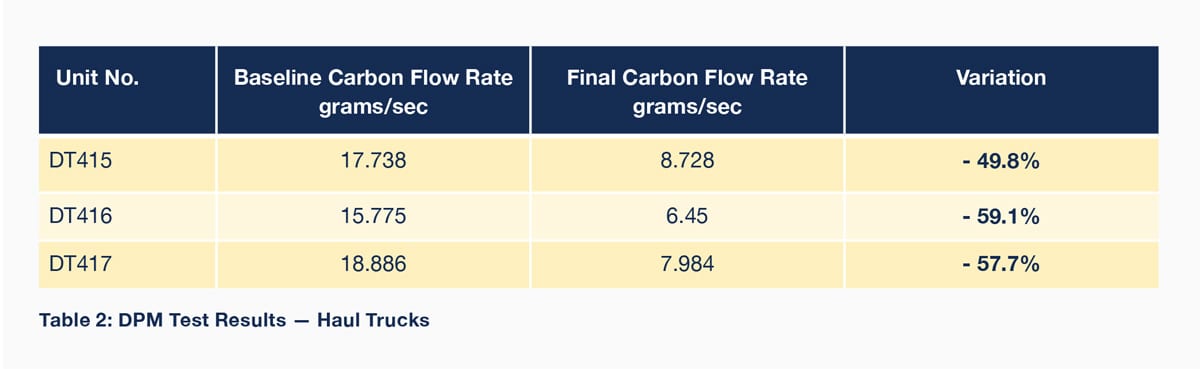

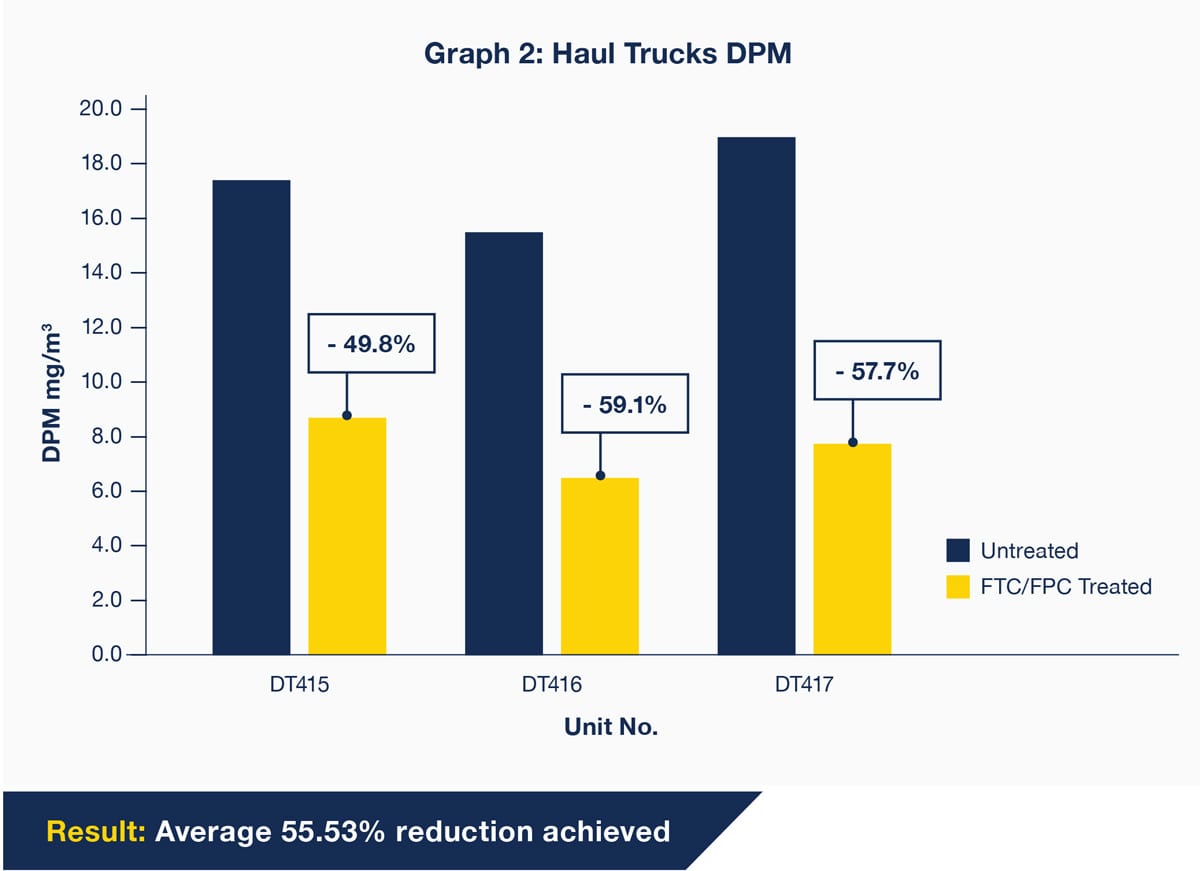

DPM Test Results – Haul Trucks

Independent scientific testing has proven large reductions in DPM following FTC/FPC treatment

of diesel. Tests conducted on the three tests trucks confirms that these significant reductions are also provided in the field applying MDG 29 test procedure.

Conclusion

These engineering standard tests conducted on three haul trucks provides evidence of an overall average fuel consumption reduction of 5.07% and average reduction in harmful diesel particulates of 55.53%.

This equates to significant financial savings in fuel consumption, reduced carbon emissions and diesel particulates, while also providing ongoing maintenance benefits due to a cleaner, more complete combustion. Maintenance benefits equate to less equipment downtime, also adding to the ongoing financial savings.

To download the full report, click here.