Regen problems? How to fix them!

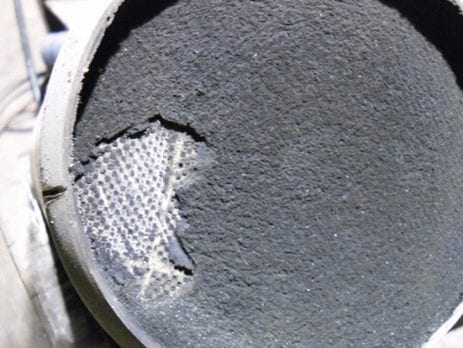

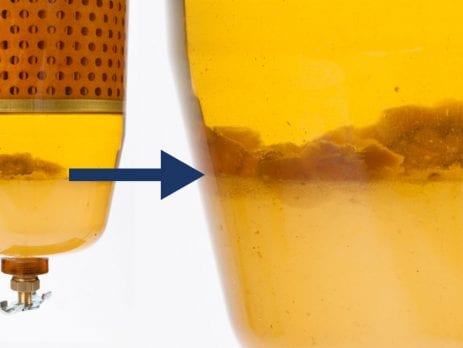

Regen problems generally arise where city driving, excessive idling or light duty cycles are encountered. Or, if other engine components such as EGR valves, turbochargers, injectors are fouled or not working properly. DPF regeneration cycles then become more frequent, and more prolonged! And…more serious! DPF’s often need replacing at a cost of...